Drilling Top Weight / CG Position Blems with Powerhouse Blueprint

Date Posted:

December 3, 2011

Category:

Blueprint Tutorials

A very common topic in the bowling internet forums is the drilling of bowling

balls with unique undrilled static imbalances. This includes balls with

unusually high or low top weights, unusually long or short pin-to-CG distances,

and unusual center of gravity (CG) locations (such as those that are not located along the line from

the pin to the mass bias locator), all caused by natural manufacturing process

variation. These conditions are usually found on discounted "blems" or

"x-out" balls, often purchased online by bowlers looking for a good deal.

This article will explore the ways in which Powerhouse Blueprint can make the

drilling of such balls much easier on the pro shop operator.

Definitions

Before we begin, we'd like to establish a few definitions regarding an undrilled

ball's static imbalance so that there is no confusion going forward. First

off, most bowling ball manufacturers specify two parameters on the ball's box

relating to undrilled static imbalance:

- Pin-out distance: This is the distance of the CG mark to

the pin. This is often listed as a range of distances, such as 2"-3" or

4"-5".

- Top weight: This is the magnitude of the static

imbalance, usually listed in ounces.

For asymmetrical bowling balls, there is a third parameter that is necessary to

describe the undrilled static imbalance, and that is the location of the CG

relative to the pin / mass bias marker line. This is often not listed on

the ball's box, but must instead be measured on the ball itself.

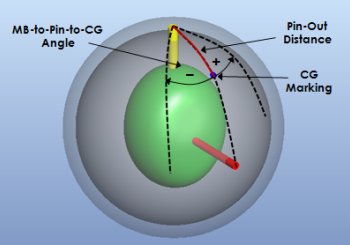

For the purposes of this article, we will use the nomenclature of Powerhouse

Blueprint in describing undrilled static imbalance of asymmetrical balls, as shown in the below image:

So then, the third parameter to describe the location of the CG is the angle

between two lines: 1) the line from the pin to the mass bias marker, and 2) the

line from the CG to the pin. The angle is expressed in degrees from -180 to

180, using the sign convention shown above. In this article, we'll refer to

this angle as the "MB-to-pin-to-CG angle", or, more simply, just the "CG angle."

Potential Challenges Encountered When Drilling Static Imbalance Blems

A lot can go wrong when drilling blems. Three main concerns of ball

drillers are listed below:

- Legality of as-drilled static weights: As we all know,

all drilled bowling balls must meet the top/bottom weight, side weight, and

finger/thumb weight requirements of the appropriate governing body (the USBC,

for example). With blems, the tendency is to be extremely conservative

with the layout used in order to be certain that the static weights will be

legal once the ball is drilled.

-

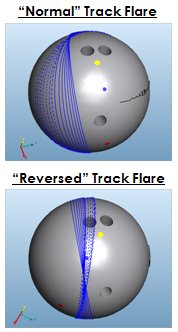

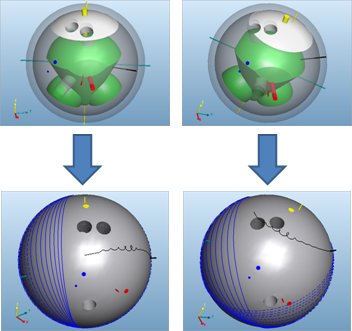

Reversing of track flare / flaring over a hole: When

drilling blems, it isn't unusual to use pin and mass bias placements that stray

from a ball driller's comfort zone, leading to concerns that the drilled ball

will flare over one of the ball's holes when thrown (which is an extremely

undesirable condition). An example of a ball with reversed track flare is

shown to the right in the bottom image. This ball will roll over the

middle finger hole during the last eight revolutions. Clearly, the

down-lane bouncing caused by this will have a very bad impact on the ball's

reaction.

Reversing of track flare / flaring over a hole: When

drilling blems, it isn't unusual to use pin and mass bias placements that stray

from a ball driller's comfort zone, leading to concerns that the drilled ball

will flare over one of the ball's holes when thrown (which is an extremely

undesirable condition). An example of a ball with reversed track flare is

shown to the right in the bottom image. This ball will roll over the

middle finger hole during the last eight revolutions. Clearly, the

down-lane bouncing caused by this will have a very bad impact on the ball's

reaction.

- Undesired on-lane ball reaction: In large part, the change in

ball reaction that a ball driller can impart through the choice of drill pattern

and balance hole position is caused by the resulting change in the flare

characteristics of the ball. This is due to the potential of track flare

to significantly change the amount of friction experienced between the

coverstock and lane when thrown, which is a function of the degree to which the

track flare rings overlap (generally speaking, tighter track flare ring spacing

results in lower friction and wider track flare ring spacing results in higher

friction...however, there is a point of diminishing return as flare ring

separation goes beyond a certain value). Since, as already stated above,

blems often require unconventional drillings that stray significantly from

well-understood drillings, it is entirely possible (and common) that a ball

driller could intend to drill a ball to flare very little, but accidently end up

with a ball that flares a lot (or vice-versa).

Now, with these potential problems in mind, let's take a look at how Powerhouse

Blueprint can help. We'll first outline a very high-level process and then

we'll look at a specific example.

Blueprint Ball Drilling Process Overview

What follows is a general process to follow for best results when drilling

bowling balls in Powerhouse Blueprint. This process applies to blems as well as

non-blems:

- Weigh and the undrilled bowling ball on an accurate (and calibrated) static

imbalance measurement device to determine its actual CG location and top weight.

While the manufacturer's CG mark and supplied top weight value are generally

reliable, it doesn't hurt to measure (and remark, if necessary) the ball yourself so that

you don't run into any unpleasant surprises after you've drilled the ball.

- Measure the pin-out distance and CG angle. This can be done quite easily using

standard pro shop measurement tools, such as the Pro Sect™.

-

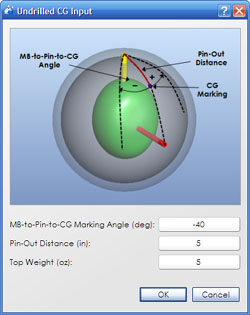

In Powerhouse Blueprint, load the appropriate bowling ball from the ball library

and then perform the core shifting operation to give the "virtual" ball the same

static imbalance as the actual ball to be drilled. This is done by

clicking Ball Operations => Shift Core from the main menu or by

clicking the corresponding toolbar button. For example, if the ball you

are drilling has 5 ounces of top weight, a 5 inch pin-out distance, and a -40

degree CG angle, you would enter these values

as shown to the right.

In Powerhouse Blueprint, load the appropriate bowling ball from the ball library

and then perform the core shifting operation to give the "virtual" ball the same

static imbalance as the actual ball to be drilled. This is done by

clicking Ball Operations => Shift Core from the main menu or by

clicking the corresponding toolbar button. For example, if the ball you

are drilling has 5 ounces of top weight, a 5 inch pin-out distance, and a -40

degree CG angle, you would enter these values

as shown to the right.

-

Virtually drill the ball using Blueprint however you like,

modifying the various drilling parameters (including balance hole position,

size, and pitch) to achieve the desired result. At this point of the process

"desired result" simply means that you drill the ball such that it is statically

legal and that the positive axis point (PAP) is placed in a location relative to

the min and max RG axes such that the ball's track flare will be close to what you want to see on-lane

(pin / mass bias placement relative to PAP, RG contours, etc. will be covered

in-depth in a future post, so we apologize if this description is a bit vague

right now).

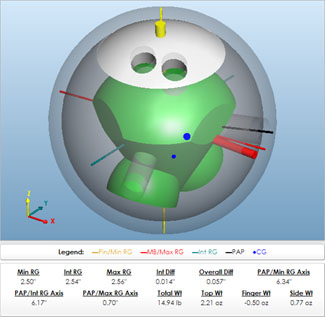

To continue our example, suppose we want to drill this ball to

flare very little. To do this, we'll attempt to position the PAP so that

it is far (approximately 6 inches) from the min RG axis and close (approximately

1 inch) to the max RG axis.

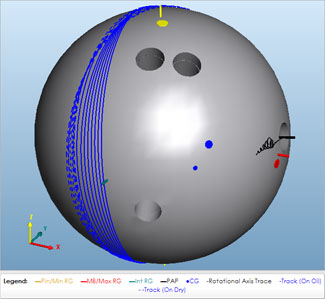

In this case, we've achieved this goal with a

drilling that places the pin 6 1/8 inches from the PAP with a 10 degree

MB-to-Pin-to-PAP Angle and a 30 degree Pin-to-PAP-to-VAL angle (commonly

referred to as a 10 x 6 1/8 x 30 drilling), with a large (1 inch diameter and 3

inch depth) balance hole on the PAP, pitched 2 inches horizontally away from

grip center. This is shown in the image above.

To continue our example, suppose we want to drill this ball to

flare very little. To do this, we'll attempt to position the PAP so that

it is far (approximately 6 inches) from the min RG axis and close (approximately

1 inch) to the max RG axis.

In this case, we've achieved this goal with a

drilling that places the pin 6 1/8 inches from the PAP with a 10 degree

MB-to-Pin-to-PAP Angle and a 30 degree Pin-to-PAP-to-VAL angle (commonly

referred to as a 10 x 6 1/8 x 30 drilling), with a large (1 inch diameter and 3

inch depth) balance hole on the PAP, pitched 2 inches horizontally away from

grip center. This is shown in the image above.

-

Virtually throw the ball in Blueprint to see if it flares as desired. At this step,

it is critical that we make sure the ball is not flaring over any of the holes.

As shown to the right, our track flare in the above example looks to be exactly

as we've desired. If, alternatively, we had chosen a drilling that

resulted in an undesirable flare pattern, we could easily return to Step 4

above and make the necessary adjustments.

Virtually throw the ball in Blueprint to see if it flares as desired. At this step,

it is critical that we make sure the ball is not flaring over any of the holes.

As shown to the right, our track flare in the above example looks to be exactly

as we've desired. If, alternatively, we had chosen a drilling that

resulted in an undesirable flare pattern, we could easily return to Step 4

above and make the necessary adjustments.

Other Possible Drillings for the Example Ball

To illustrate the power of Blueprint's virtual ball drilling and on-lane motion simulation capabilities, we'll now continue the

above example and show a variety of drilling configurations that could be used

to achieve different on-lane reactions. To be clear, please keep in mind

that these are not drilling recommendations that we think people should be

using; rather, these are just random examples of ways in which this particular

ball could be drilled to illustrate the point that your options regarding the

drilling of blems aren't necessarily as limited as you might think they are at

first glance.

Here are two possible drilling options...

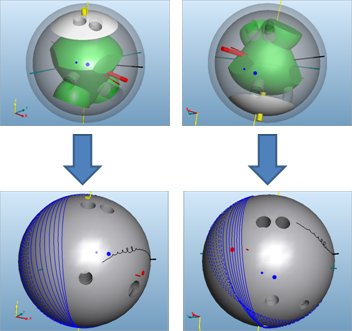

...and, here are two more, all four of which are legal with respect to static

imbalance.

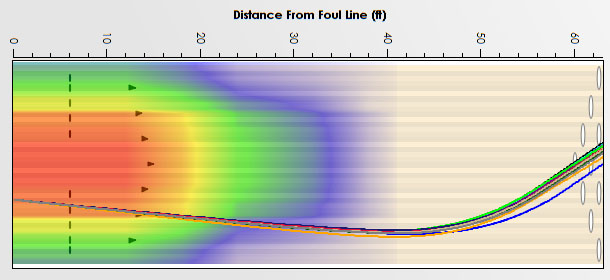

In terms of on-lane reaction, the drillings shown above result in a total hook

variation of about 5 boards, largely due to the changes in the track flare of

the ball:

Tips and Recommendations

We'll close this post by providing a couple of tips that you should keep in mind

when using Blueprint for simulated ball drilling (particularly in cases like

those shown here involving blems):

- Accurate bowler delivery input is critical. Make sure that you know a

bowler's PAP, ball speed, rev rate, axis tilt angle, and axis rotation angle

before attempting to use Blueprint for anything like what has been shown in this post.

Small errors in any of the input parameters can result in a drilled bowling ball

that isn't going to perform as predicted.

- Blueprint is not a replacement for actually checking the as-drilled static

weights on the scale. The static weights in Blueprint will track pretty

closely with the actual static weights measured on the scale, but there will be

slight differences.

- Because Blueprint can't perfectly predict static weights, try to leave yourself

an "out" when you have predicted static weights that are close to the legal

limits. What we mean by this is that you should always, when possible,

have a plan for what you can do to fix a ball that has already been drilled, but

checks slightly illegal on the scale. For example, if Blueprint predicts

0.90 ounces of finger weight, make sure that you have some room to increase the

finger hole depths in the event that the static weight scale shows the drilled

ball to have 1.10 ounces of finger weight, for example. You can, in many

cases, employ the same strategy with balance hole depths. Leaving yourself

an out post-drilling can save you a lot of trouble and we highly recommend it,

when possible.

- Don't "push your luck" too far. For example, try not to drill a ball that

comes within 1/64" of hitting one of the holes in the Blueprint simulation. Why?

Your bowler delivery parameters are not perfectly accurate, the mass properties

of the real ball aren't 100% accurate due to manufacturing process variation,

and the bowler will have natural variation in release consistency. For

these reasons, a ball that doesn't hit any holes in Blueprint may occasionally

(or frequently) hit a hole in real life if you haven't left yourself enough of a

"buffer" to allow for these variations. For an average bowler that has

never been Blueprinted by you before, we would recommend that you try to

maintain a 1 inch buffer between the closest track flare line and hole edge.

For elite bowlers (with consistent releases) and those that you have a lot of

experience with, you can relax this requirement slightly.

We hope this post has been informative, helpful, and useful to you in getting

the most out of Powerhouse Blueprint. In a future post, we'll share with

you some additional information about using Blueprint to squeeze that last

10-20% of performance out of a ball using some (as far as we know) previously

unused drilling methods.